Due Diligence for Sustainable Procurement

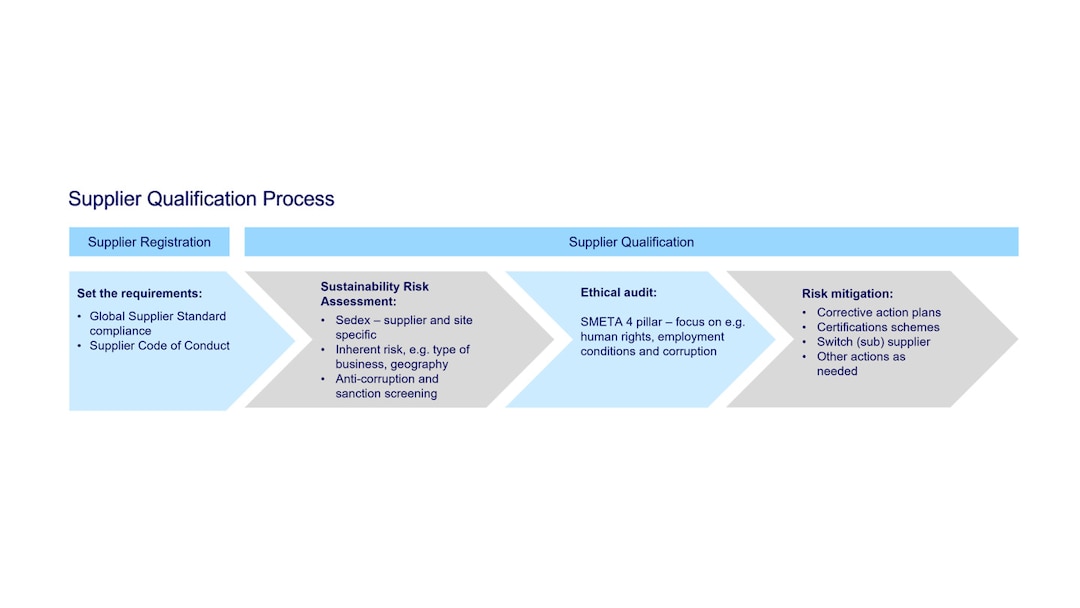

To safeguard sustainability considerations and to minimize any environmental, social, and ethical impact related to our procurement activities and suppliers, we have several checkpoints as part of our supplier qualification process that are covering sustainability issues and risks.

Essity Global Procurement applies a risk-based approach when assessing individual suppliers as part of the supplier qualification process as well as when evaluating the entire supplier base in the yearly strategy work.

1) Set the Requirements

Our requirements on suppliers are defined in our Global Supplier Standard which also contains our Supplier Code of Conduct. Suppliers should commit in writing that they will honor the requirements in this document and pass on similar requirements towards their own suppliers. Failing to respect our Global Supplier Standard can lead to discontinued business relations.

2) Sustainability Risk Assessment

All suppliers are assessed from an inherent risk point of view, i.e., the risks that often are associated with the kind of business activity, raw material, technology or region of the supplier.

Essity requires that suppliers use Sedex (Supplier Ethical Data Exchange) to conduct a self-assessment linked to working conditions, environment, business ethics and health and safety. A risk profile of the supplier is obtained through a combination of a questionnaire and several different risk indexes.

Furthermore, all suppliers are screened related to ethical business, anti-corruption, and sanctions.

3) Ethical Audit

If there are any indications of sustainability risks, we will request an ethical audit to be performed at the premises of the supplier. The preferred format is SMETA audit (Sedex Members Ethical Trade Audit) that focuses on areas such as human rights, employment conditions and corruption. The result from an audit is used as key input for the decision to continue the business relation with supplier, to perform corrective actions or cease collaboration.

4) Risk Prevention and Mitigation

Based on the overall risk score calculated for the supplier Global Procurement decides if the supplier is to be approved or not. In addition, different types of mitigating actions can be agreed for the suppliers, such as a corrective action plan in case of non-conformities.

A detailed analysis of a supplier or a material can also conclude that the main risk is not with the direct supplier, but that it is laying further upstream in the supply chain. If this is the case, there are several different mitigation alternatives, e.g. to implement certifications where external bodies, using audits and chain of custody, safeguard certain standards.

Austria

Austria  Belgium

Belgium  Canada

Canada  Denmark

Denmark  Finland

Finland  France

France  Germany

Germany  Italy

Italy  Mexico

Mexico  Netherlands

Netherlands  Norway

Norway  Poland

Poland  Spain

Spain  Sweden

Sweden  United Kingdom

United Kingdom  USA

USA