Risk Management

Proper due diligence requires efficient risk management - a systematic approach to identify, analyze, evaluate, monitor, and treat risks. At Essity, risk management is performed for both new suppliers and for existing suppliers. The applied risk-based approach is a method of managing risks by identifying, prioritizing, and addressing them according to their potential impact and probability. For this purpose, Essity has a Supplier Risk- and Resilience Management Procedure to secure supply in accordance with agreed contracts, specifications, sustainability requirements and to reduce cost, to avoid regulatory fines and reputational harm on Essity Brands.

Establish the context

Establishing the context is necessary to customize the risk management process so that the business needs are met, and to ensure effective risk assessment and appropriate risk response. First step in Essity’s Risk- and Resilience Management Procedure is to identify suppliers that have a high or very high business impact on Essity brands and / or on Essity sourcing and production. The business impact parameters that are evaluated are: Sustainability/ESG, Regulatory Compliance, Material / product specific regulations, Product Quality and Safety and Operational Impact and Sourcing Complexity.

Country of Origin

Essity has global manufacturing, however most production sites are located in Europe and North America. Some sites are located in Australasia, India, South Africa and South America. Essity sources many raw materials and chemicals locally, often from supplier sites that are part of large multinational corporations based in Europe and the USA. This is conscious choice by Essity to reduce social and ethical risks throughout the supplier base, as best practices and relevant certifications and standards have been implemented across all sites throughout the entire supplier company.

Some raw materials are closely associated with specific regions due to natural reasons, such as wood pulp or cotton. Many times, those materials are considered to primarily have risks several tiers away, in the beginning of the value chain. Essity takes further measures here, such as audits of sub suppliers, or chooses certified raw materials that guarantee more sustainable extraction and production.

Origin and Risks

Essity is taking location of supplier and origin of raw material into consideration when assessing risks. The same material can entail different risks depending on the area where it is manufactured or grown, whereas other items can have similar risks regardless of where they are produced and delivered, such as certain services.

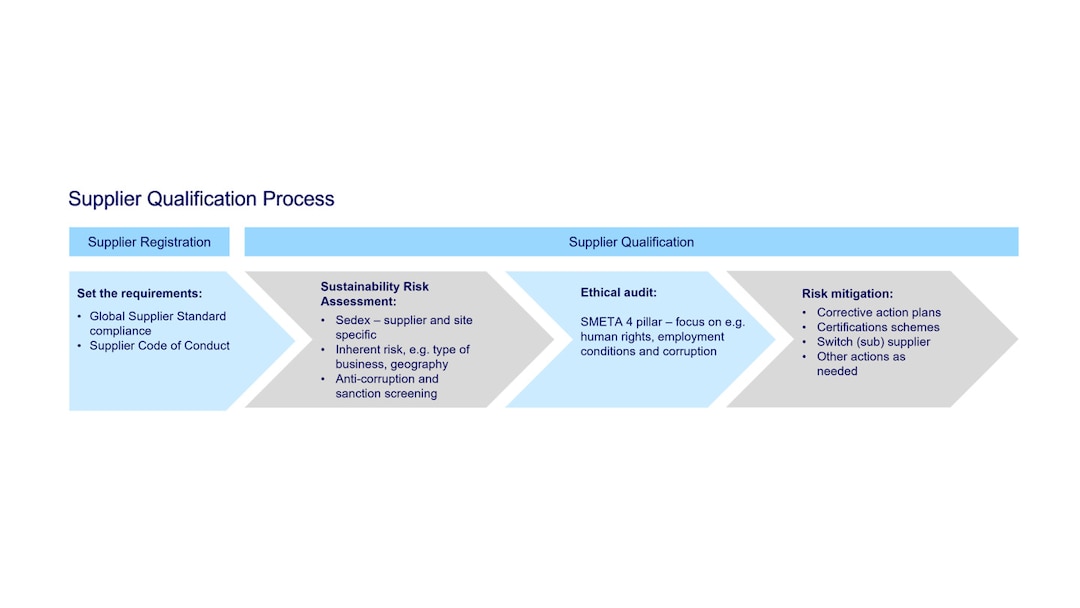

Sustainability Risk Assessment Well Embedded in Established Routines

To safeguard sustainability considerations and to minimize any environmental or social impact related to our procurement activities and suppliers, we have integrated the requirements into our standard processes and normal routines. For Essity, there are several checkpoints in the mandatory supplier qualification process that are covering sustainability issues and risks.

Austria

Austria  Belgium

Belgium  Denmark

Denmark  Finland

Finland  France

France  Germany

Germany  Italy

Italy  Mexico

Mexico  Netherlands

Netherlands  Norway

Norway  Poland

Poland  Spain

Spain  Sweden

Sweden  United Kingdom

United Kingdom  USA

USA